Ok, my Team Lead at work was a former Automotive industry mechanical engineer. They have lots of springs. I asked him why this wouldn't work. This post is about to get engineering-y.

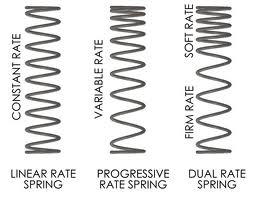

It can be done, but not with the current constant spring diameter. Or in other words, this won't work:

Why? You have two springs in series which means the spring constant will even out. It won't have two separate feelings, it will just blend into one weight that we'll call XX g. You can see the equivalent spring rate formulas

here.

Now what can be done is if you have a Topre like spring where the diameter of the spiral is variable (aka "beehive" spring). Like this picture

from Baldux on DT:

Either that or make the actual gauge of the wire variable (thinner or thicker wire) could get you what you want. I bet that either the beehive or variable wire gauge springs aren't cheap and we'd have to figure out how to fit them in an MX switch without binding.

Hope this helps a little.