Inviting all geekhackers to weigh in!

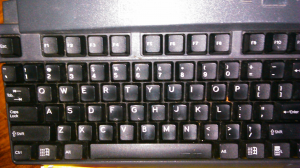

I got the following keyboard from Ebacho recently. The price was very nice, and the keyboard itself is very solid. Here it is. It is one of the heaviest Cherry MX keyboards I have ever used.

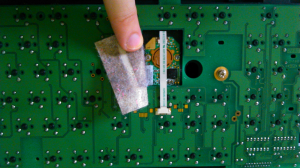

One note (absolutely not a complaint about Ebacho; I just like observing such things). Keyboard was incredibly dusty inside. Bunnylakeís entire family was living inside aka many big dust balls. Yet not a single screw was even slightly corroded. Of course, Ebacho lives in California and gets his stuff from recyclers in CA. In a humid environment like Singapore, the situation would probably be reversed. Tiny dust balls, and lots of rust.

My observation about the dust bunnies is significant. This is the dustiest Cherry MX keyboard I have ever come across. (And I have bought many filthy ones from Taobao to desolder clears from!) I suspect the dust is getting in through the credit card swipe at the top. Since I donít need to use that credit card swipe (hint, hint, guys, especially people like Fohat who have a good sense of mechanical fixes) I need to fix it such that dust doesnít go inside the keyboard anymore.

I was gratified to find that the trackpoint works well. Not so happy to find that the trackpoint has sucky switches. Of course, thatís going to change with all of your help!

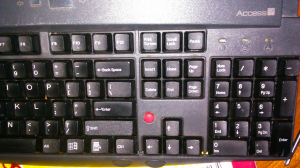

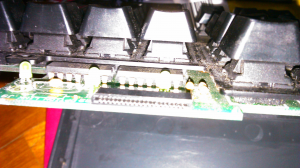

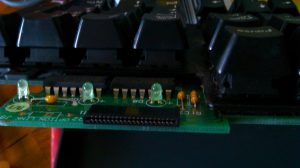

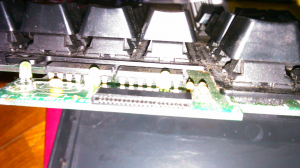

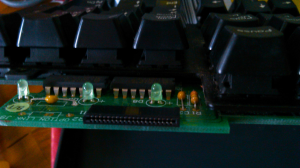

OK These are the trackpoint switches. Theyíre not actuating well. Time to change. But what can I change them to? (Need some names and specifications.) Also I note that the soldering is kinda odd. I canít see the contacts. Are the contacts merely too short, and hidden inside the dual layer PCB?

OK, and here you can see that the keyboard has what seems to be two sealed USB ports and a covered serial port at the back. Not sure what they do. I hope keyboard can be turned into a USB hub, although I really could not remove the plastic cover from the usb ports. (Hints, guys?)

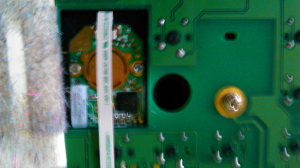

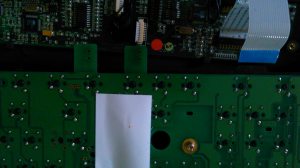

Now take a look at what I deem is the weakest link in this keyboard. The kb and trackpoint communicates with the controller only through one very flimsy cable. This one. I counted 21 contacts. Is it possible (theoretically) that if I connect these 21 contacts to a teensy++, I can have my own tiny little keyboard controller? I donít need to go through that big controller? I am really not appreciating all the extra stuff which adds unnecessary weight and size to the keyboard. [Having read a bit I do understand that the teensy doesnít come with mouse control, but of course again I am hoping that Soarer has been secretly working on mouse support.]

Since I donít have good soldering skills I am wondering how else to connect the 21 contacts to a teensy/ arduino. Really find that gigantic controller quite unnecessary.

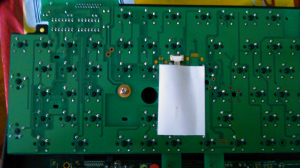

OK, hereís the PCB. I am not familiar with trackpoints, so please guide me. I understand trackpoints are hard to get, and donít want to destroy it accidentally while desoldering the Cherry MX blacks. Does anyone have advice regarding the trackpoint?

Also note that the switches seem to be PCB-mounted with diodes, although there is a plate. I donít have much experience, but I have never seen this kind of setup before.

OK, thatís it for now; Iíll wait for people to weigh in before deciding what to do. In general I am hoping to do a plate mod to allow switches to be changed, and I am hoping to change the return key to ISO (notice the PCB allows it). I also want to do something about the lousy trackpoint switches, as well as sealing off the keyboard at the top (remove the credit card swipe as well). I would like to liberate the two USB ports at the back and turn this into a USB hub.

Judging from the weight I am not dealing with an aluminium plate, so I guess thereís going to be a lot of laborious cutting involved and the eventual fit wonít be good. Since it is my little finger striking the return key, I think I can afford to be Ďpcb-mountedí there i.e. Iíll cut the plate big enough to allow the switch to be placed in the ISO position. Since my cutting wonít be exact, the switch wonít fit exactly and wonít be supported by the plate when in use.