The Abko Hacker K935P is a relatively affordable NIZ switch offering (if it is even still manufactured). Chyros' video on it is what motivated me to purchase one a while back. Mine was "renewed" by Amazon, which apparently basically means that it has been thrown off of a building, stored open long enough to collect a significant amount of dust, then delivered by Ace Ventura.

I resolved all of the initial usage problems I had with it and tried to fix all of the various cracks in the case with high temperature hot glue. The case is some kind of cheap/brittle plastic, definitely not aluminum as Chyros' review suggests. The plate is also some sort of cheap/brittle plastic, so the posts molded into it that are used to screw the PCB into place just break off (often just trying to get the screws snugged down firmly). Mine arrived with at least 25% of them broken off and I broke off another 25% myself just working on the thing. I initially just filled the resulting holes with high temperature hot glue enough to overlap the PCB in place of them. That worked well enough for me.

Months later, my coworker who had very little experience with mechanical keyboards wanted to try something tactile. He used this board for a time, but one of the keys wasn't always registering. He liked it a lot, but set it aside.

Recently, I finally set out to permanently repair this board and hopefully reinforce it at the same time to make it at least slightly less garbage-tier in terms of construction (in no small part due to the fact that I needed to remove all of the hot glue to even get back at the conical springs between the PCB and the rubber dome sheet).

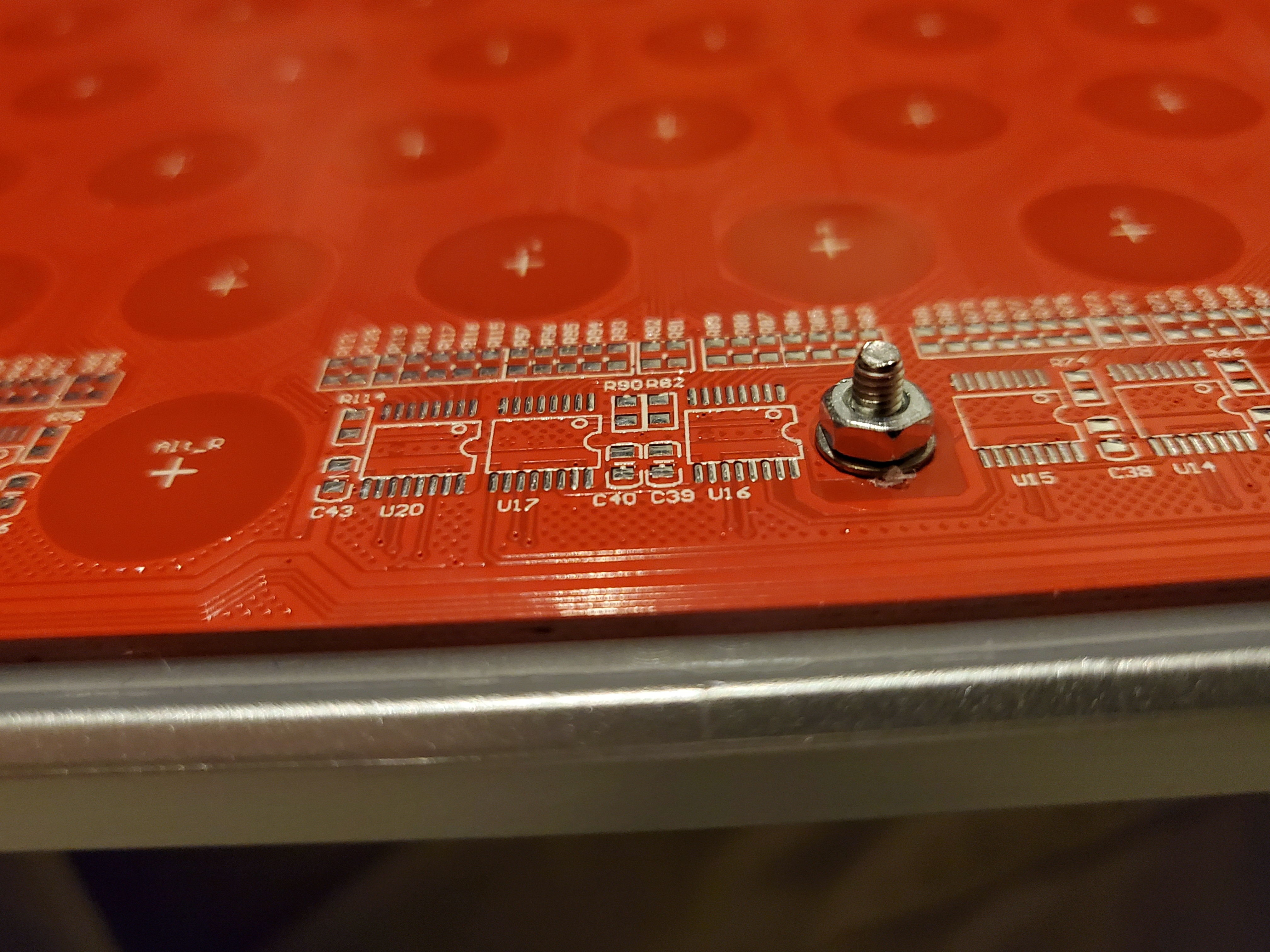

My solution was to drill out the old plastic posts straight through the case so that I could replace them entirely with screws, nuts and washers. I chose to use the following:

M2.5x12mm machine screws (it turns out even standard pan head screws do not obstruct the caps on the downstroke)

M2.5 hex nuts

M2.5 washers

Wherever the screw head intersected a thin raised portion of plastic, that plastic was broken or cut off, as the edge of the cap above also usually hovered above as well. With the top row of keys, I had to put significantly more time and effort into drilling through the case. I think there's actually some metal reinforcement in that area, between layers of plastic.

I had to take the resulting sandwich back apart a few times and tweak the tightness of the screws in order to get every key working and for it to feel as smooth as it did before the mod. If you really torque everything down, I think you end up smashing the rubber between more than it should be. I ended up settling on just holding the head of the screw in place with one finger and tightening the nut with a nut driver (5mm in this case) until it felt firm enough to not back out.

The result should, hopefully, be something a lot more durable and serviceable than the original design.