So gave my first go at desoldering/soldering to change the layout of a DZ60 I bought from r/mm. Went from tsangan to arrows, essentially adding and shifting switches. Ended up with a few pins at the end of a row that don't work (I think).

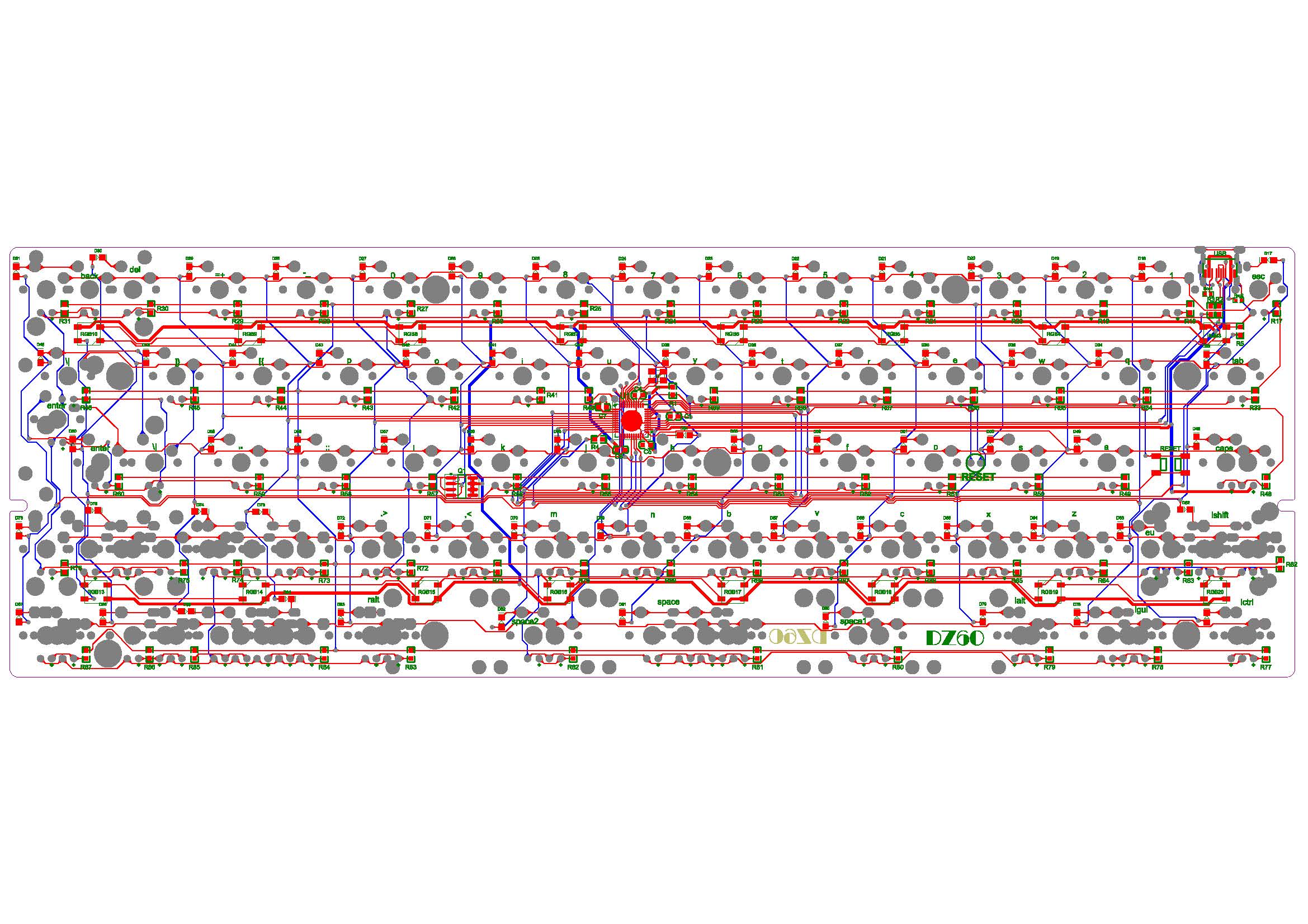

So I either borked it or it's a layout thing. I don't think it's a layout thing because the extra switches added on the bottom row work, so I'm guessing I just fudged something up during soldering on R4. I saw this diagram for how the traces are laid on a different post and had a thought that maybe I somehow broke one on the lower pins of the row? I was thinking I had to maybe bridge something but I'm really not sure how to proceed. A pointing in the right direction would be appreciated.

EDIT: Tested the upper pins with other lower pins, and they work. Tested the lower pins with other upper pins and they have no response. Not sure how that helps me but figured info was info.

EDIT2: Decided to bridge the working bottom pin and the non-working one on the assumption that that's where the break was, and it seems to have fixed the issue!

I don't have wire so I just cut up an ethernet cable, lmao.