Hi all,

As many of you may know, SPRiT, Thic Thock, and others have advertised and sold progressive springs for a while. These springs claim to be nonlinear, having a lower spring constant before the approximate actuation point, and an increasing spring constant after, to provide a more cushioned bottom out. SPRiT, on his website, provides the following image for what the force curve for his progressive and complex springs should roughly look like:

These springs are wound tighter on one side than the other. SPRiT's springs look like this, for instance (image from his site):

Nonlinear springs are known to exist - for example,

this article from an industrial spring manufacturer describes some of them, including buckling springs, conical springs, springs of varying diameter, and "dual rate" springs that have a tighter winding on one end. So far the "progressive"/"complex" springs sold by SPRiT, Thic Thock, and others have all been of the last variety, which have a constant diameter but a varying winding pitch on one end of the spring. In theory, these springs work by the tighter end compressing first, and the coils on the tighter end bumping up against each other, which provides nonlinearity. A seller of industrial springs

has a nice animation of how these work. However, as implemented in a keyswitch these don't really seem to be very nonlinear.

As some of you may know I recently designed and built an open-source force curve meter, the files which are published on Github

here. The curves of various switches, frankenswitches, and springs I've measured so far are published in a directory on the Github,

here.

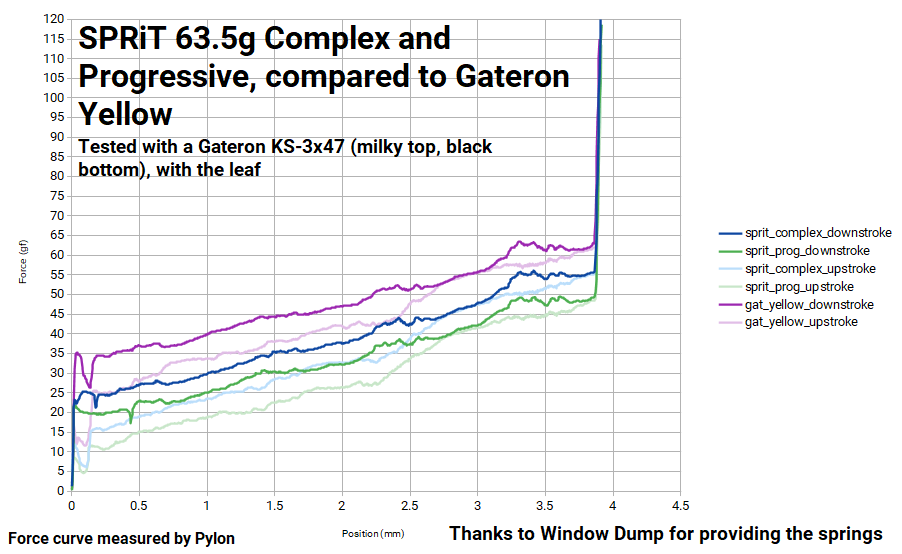

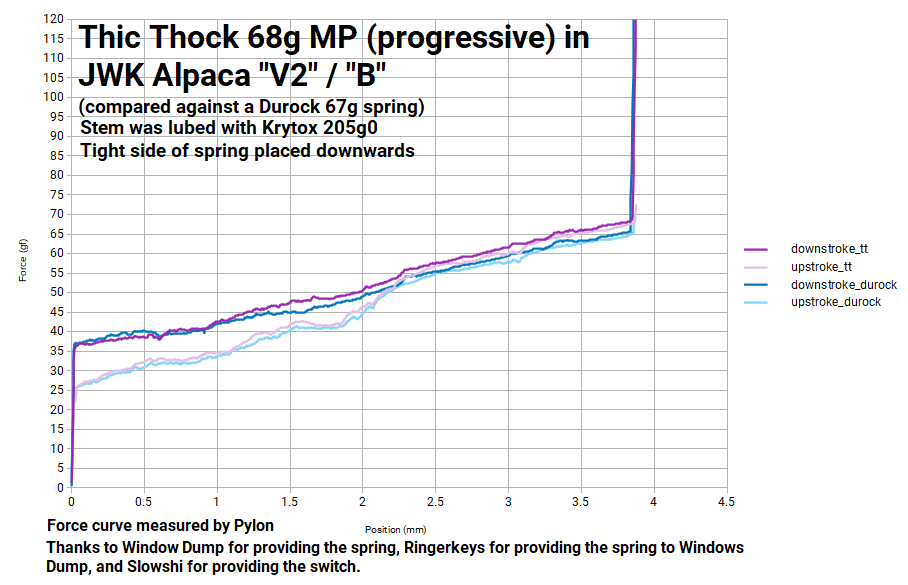

Windows Dump (I don't believe he's on Geekhack, but he goes by that on Discord) recently lent me a gBoards.ca SPRiT spring sampler, and also various Thic Thock DL and MP springs. I measured the 63.5g SPRiT complex and progressive springs from the sampler, and the Thic Thock 68g MP springs. The SPRiT springs I placed in a Gateron Yellow (one test with the leaf, and another test with the leaf removed), and the Thic Thock spring I placed in a JWK Alpaca "V2" / "B" that Slowshi lent me (the Thic Thock spring is a bit wide diameter wise, and tended to catch on the stem in the Gateron Yellow stem, so I used the Alpaca instead). I did the leafless Alpaca tests using a "V2" / "B" bottom housing from a JWK T1 from which I removed the leaf.

The results are here - I compared the SPRiT springs to the stock Gateron Yellow spring (which is nominally 63.5g), and I compared the Thic Thock spring to a Durock 67g spring when installed in an Alpaca switch. For the leafless measurements, I also plotted them against a theoretical perfectly linear line, which I made by plotting the measured values at x=0.1mm and x=3.8mm and drawing a straight line between them.

Obviously these don't look very nonlinear. The Thick Thock 68g MP pretty much looks linear and very similar to the Durock 67g spring when installed in an Alpaca switch. The SPRiT springs deviate about 1-2gf from linear, and also don't seem to behave nonlinearly by very much compared to a regular Gateron Yellow spring. The SPRiT springs are also much lighter than the 63.5g claimed.

I don't know if this is an implementation issue with these particular "progressive" springs (the tighter wound sections on the SPRiT and TT springs are relatively short compared to the regularly-wound portion of the spring, and seemingly too short to have much of an effect), or if keyswitches just inherently don't provide enough travel and compression for progressive springs to really enter their nonlinear regime. I also haven't had a chance to test other progressive springs, and it is possible that some of them in fact behave nonlinearly as expected. But in any case, you should probably be skeptical about purportedly nonlinear "progressive" springs for the time being, until you see measurements that validate their claims.

(edit - fixed a typo on a URL.)

(edit Feb 26 2022 - fixed broken URLs)