You're welcome.

Keep in mind, I'm being overly critical, this can work as you had it. I'm sure a few are going, "wow that's overkill", it is, but I prefer to look at it from a best case/long term perspective.

You have a brass plate and a marble plate, in a wood case and neither is being used structurally. You built your whole case to be supported by the thinnest bit of wood in the case using glued in inserts. It's backwards.

First off..

Bolt the top to the plate, use brass inserts, small screws or simply epoxy it. I would recommend lots of small screws. Yes, this makes the top decorative (as most are), but also less likely to warp. Splay shouldn't be an issue, the wood isn't under any stress besides holding itself in place.

Second,

Tap threads into the plate, epoxy some nuts, use nutserts or use Chicago bolts, one way or another bolt the plate all the way through the lower wood and through the marble. Effectively clamping the wood between each and using the heavy, strong marble as your foundation, not simply a bolt on weight. This will make for a much more solid case. This also allows for a much simpler center part as you will see.

Third

Remove the wood in the bottom, if we use the marble as a structural part, this is no longer necessary, allowing for a much lower profile base. This part can now be water jetted, lasered, jig sawed out of ABS, cast epoxy, plex, polycarb, wood, plywood, whatever. It's simply a ring with a few holes. You could even just buy a bunch of appropriately sized spacers and use those (don't do this, it's just to emphasize how little it matters).

Fourth

On the rear, that sharp edge is a disaster waiting to happen.

Instead of wedging down into the marble, I know it's to fight splay but you are counting on some seriously tight tolerances from stone and wood to make that work without bind (stressing the inserts) or having an unsightly gap. Instead of an inward downward slope, go with a flat or outward slight down slope. You won't see any gap unless you get down below the horizon of the keyboard. If it warps it warps, your attempt to fight it with tolerances is a valiant one, but not one you will likely win. Making the changes above reduces the stress on it anyhow so it's less likely to warp in the first place.

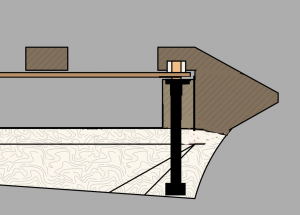

Here's a down and dirty image to give an idea of the changes. You will have to excuse the quality and sort of figure out the top bolts but I think that part is the easiest to explain.