Thanks for the assist, much obliged sir!

apologies if this is too off topic:

so a sweet metal cased keyboard with the custom layout i posted would be freaking awesome

my thought was that maybe this custom hard wired plate idea could be extended into a full custom keyboard

I did a quick search and didn't really see anything on making a case out of a sheet of stainless steel but that's what I'm thinking about.

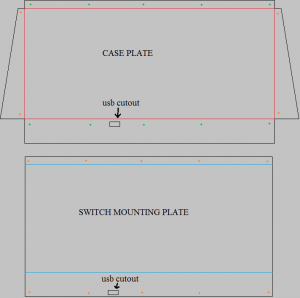

here's a quick ms paint concept scrawling:

green dots are through holes, orange dots are tapped for screwing into

imagine bending flaps out of the page on red lines and into the page on blue lines

switch plate goes inside the case plate

screw in L brackets on the outside of the corners for some structural integrity

make flaps on the case plate longer than the ones on the switch plate to create a nice lip

I feel like if it is possible to bend decently thick gauge stainless steel this could make a real solid feeling case. Anyone have any thoughts? see any problems?