So today I did the first assembly steps and can finally share some actual pictures.

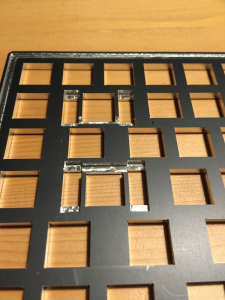

Here are some photos of the front plate, also showing the pockets which were milled to allow for clearance around the stabs and stab wires

Because of the plate's thickness the switches are only held in place by friction (apart from being soldered to the PCB, of course), but when dry-fitting some switches for a test it showed that they sit in there quite securely, yet are easy enough to pull out without needing tools, in case I ever want or need to replace them.

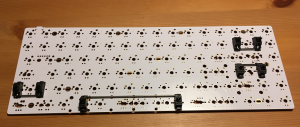

The first action was mounting the stabs to the PCB. I used GMK screw-in type stabs which came with nylon washers. It's not that you absolutely need the washers (at least for the layout I am going to use), but I used them anyways, just to be on the safe side.

I didn't do any clipping, lubing, band-aiding etc., so just mounted them factory-default.

Next up is soldering...