I've been toying with the idea of making a 60% wedge type case for a while now. I'm slowly learning CAD but got side tracked by real life and invited a friend of mine to help out (although I am still convincing him to get a mech).

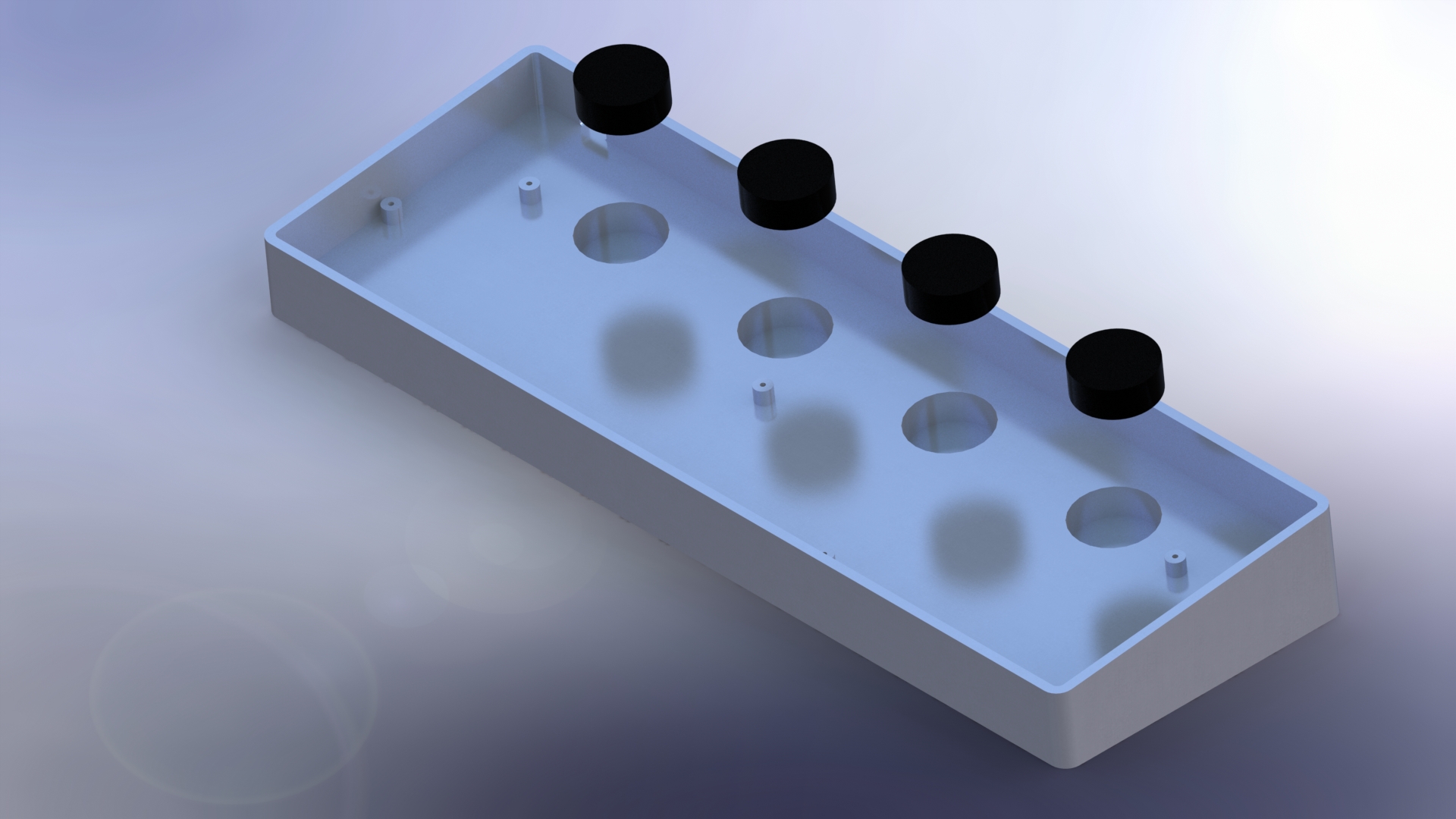

RENDERS!

We forgot to add the recesses for the bump-ons.

As is, it will be machined from T6 6061 aluminum. I could go with 7075 but it would be overkill and just add on to the price. The inserts will be made of 4140 steel and installed on the inside of the case to keep the case bottom clean. Probably going to have something engraved on the bottom but I haven't decided yet.

The case is estimated to weigh 1 to 1.5 kg (2.2 to 3.3 lbs). The angle is 13-degrees (a personal preference) but I might dial it down to 11.

Another possibility is that it will be machined from wood but still have steel inserts for additional weight. But I'd like the stand offs to be metal for durability. I'd also need to figure out how to finish the wood.

Things to do:

- I've removed the hole on the case for access to the dip switches, how much clearance do I need between the case floor and the PCB to make this compatible with PCBs with dip switches?

- Wait on quotes for materials and machining.

- Explore anodizing options

- Explore options for wood and wood finishes

More info and renders of the wood case here:

https://geekhack.org/index.php?topic=68278.msg1624280#msg1624280