Lately we've seen quite a few people wanting ďgasket mountĒ and I think it's time we discuss it.

First off,

what is gasket mount.

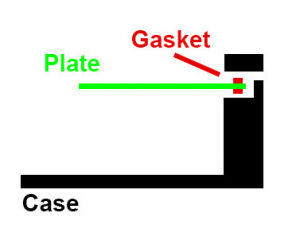

Gasket mount is a bit of rubber (or similar) between the plate or pcb and the case. The original purpose was to isolate vibration/noise traveling from the plate and/or pcb to the case. Does it work? As with most things in keyboards, yes, but as always it's not a fix for everything. Iím not sure where the idea came from but along the way some people got the idea it dampens impacts as well. While some forms of it can do this it's usually only on small keyboards such as 65% or less and then it's done more as a hack, not so much a part of the design and on larger keyboards it's a side effect.

On top mount (Plate bolted to the top cover) or bottom mount (plate bolted to the case bottom) both depicted here, the damper can be below, above, around the edge or any combination of the 3. On any keyboard like this it's really more of a side effect and minimal at best for reasons we'll get into.

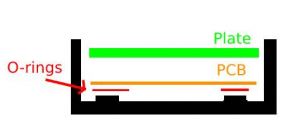

On plate-less or floating plate designs it's found under the pcb. Most of these are just people adding o-rings or foam under the pcb. It does work as we'll discuss later but it has limited applications and it can create some issues. Like I said, it's a hack.

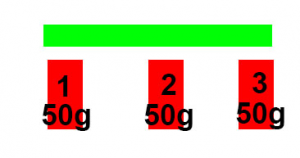

So whatís the problemLet's start with the most common thing people have with it, the suspension itself. Imagine 3 springs in a row, 1, 2, 3 with a beam across them, like this.

Ok, so this isn't a perfect example of what happens but it should get the point across because it's important and something I've seen a few times now.

If you press above spring 1 almost all your load is on spring 1 (50grams), same for spring 3 (50 grams), if you press on top of it almost all your load is on spring 3, in both instances spring 2 becomes almost inconsequential. Depending on the design it may pivot on it like a see-saw or it may slightly compress (60-70grams), but it will not fully compress as far as spring 1 or spring 3. So what happens if you press above spring 2, itís load gets spread across spring 1, 2 and 3, instead of 50-70grams your spring pressure can be as high as 150grams. There is no way to make the middle feel as soft as the ends even if you lower the spring pressure both sides they still to the pressure you will see. Again, greatly over-simplified, the point is anything in the middle is effected by everything around it. If you add more springs it doesn't change this, it's going to be that spring/damper plus those around it. What if you eliminate spring 2, you still spread a middle press across spring 1 and 3, besides, you have more than 2 keys. What this means is thereís almost no way to suspend a flat object (I.E. a plate) this way and make it consistent across the keyboard. Itís not impossible, but it is in the confines of a keyboard, and certainly not by just sticking foam, gel or some sort of gasket under the pcb or the plate.

Maybe you donít really care about it feeling consistent, I can see that, certain parts can be beneficial to be lighter and softer. Thatís part of the idea behind Realforce, many people use a stiffer spacebar, even my current board is setup that way to an extent with a few slightly stiffer springs in strategic places. The problem is you arenít able to control it well enough. You need to have it down to individual keys or at least various zones but while you can, it would take quite a lot of design work and testing.

There is still yet another issue and that is mass and the lack of dampening itself on such a large moving object. The stem in your switch is controlled by the spring and to a lesser degree lube, it may be loosely controlled but itís very low weight so it doesnít really matter. The pcb, switches and plate are not low weight, the higher the weight the more damping you need to control it. What happens if you donít? You slam the W key, the assembly goes down then starts to come back up only to slam right into your finger slamming down on S key making the impact harder than it would be had you not had any movement in the first place. So how do they deal with dampening the plate movement? Easy, they either squish the gasket down tight so it doesn't or they simply don't bother. Remember it's meant to stop vibration and sound not soften the 300 pound gorilla pounding on the keys. I think this may be where the idea gets misunderstood. On Top and bottom mount the the plate isn't just softly floating on a cushion, it's clamped, preferably tight. Yes, you could run it loose, which is what they do with the o-rings on plate-less and floating plate designs but what did you just read about consistency?

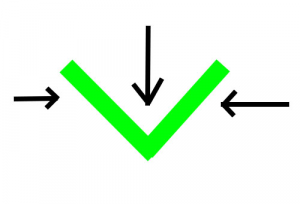

So if you can't reasonably suspend the plate, how about allowing for some flex?

The plate was never meant to flex, itís very job is to keep things from flexing and protect everything under it. While you could make it out of something flexible, cut it up or eliminate it entirely, in all cases you're kind of defeating the whole point of it being there in the first place.

That leads to the second issue and it's actually a bit more grim.

Instead of springs imagine a trapeze artist high above the floor, he slips and down into the net he goes. What happens to the net? It droops down, just as you want but what else happens? It draws in extra material from around it.

The pcb doesnít stretch, it's not elastic, it only bends (same for a flexible plate) and all that extra length has to come from everything around it and just like above it will happen at different rates. What ends up happening is you are pulling the switch bodies in half vertically

and sideways. The plastic will likely be fine, but what else is it pulling, the solder joints and the switch contacts. You may get false triggers, damage the contacts or break the solder joints. A half plate is even worse, while it will flex more easily all that load is now concentrated on the few perimeter switches. Before multiple switches would help absorb the load but here it's all concentrated on fewer switches and it's more switches doing it to them.

On keyboards with a floating plate like Tofu or GH60 or if it's entirely plate-less, mounting the the pcb on o-rings does work to a degree at avoiding the shearing issues and can give you some damping but youíre back to the issue of springs in a row, rebound and and I havenít yet seen a pcb that had even remotely equal spacing around a keyboard making consistency even worse. There's also the issue of most keyboards over 60% are using a plate and the better ones are typically top or bottom mount not a floating plate. If you do want a cushion though, this is about as close as you will get. If you do go down this road just know it's a limited group of keyboards than can do it and I'd recommend a floating plate over plateless if you want it to last for the reason we'll touch on in a moment. One last important thing to note, doing this lifts the pcb and therefore the USB port, depending on the placement and design the port may no longer fit through the hole. Make sure you have clearance or expect to cut the hold a bit larger to make it work.

And what of the PCB itself?

While fiberglass can and has been used as a spring they generally don''t have copper traces being twisted, pushed and pulled, eventually they can pop off or split. "But itís only a little bitĒ. You don't flex your pc's motherboard so why would you think flexing this is okay? You also aren't flexing the motherboard as often or doing it with a localized impacts or load. What do you think the plate was there for, looks? It's not there to make it heavy, it's there to stiffen the case and protect the PCB. This is why you don't see plate-less full size and TKL mechanical keyboards. I'm not saying this will kill your PCB right away, the point is it's bad for it, smoking kills but people don't usually drop dead after one cigarette. It may last a year it may last several but don't tell me it's good engineering.

By the way, all of this is massively worse with Kailh hot swap, now you have torque on the socket and it's mounting pads on top of sliding the switch around in the socket itself grinding parts together and losing contact. If you have them and you value your keyboard in the slightest do not try doing any of this to it. If you have hot swap, regardless of type, you need a good solid plate, it can be gasket mounted, but it needs to hold things in alignment.

The ironic part of all of this is people spending all this effort trying to put back some of the very properties they ran away from when using a plastic chassis (flex). You could easily add weight to one and avoid all sorts of pitfalls an aluminum keyboard has. Itís just silly to spend all this money, time and effort to try and replicate the feel of something you could get for hundreds of dollars less. I've said this before, if you want it to last build your keyboard like a race car, bicycle, motorcycle, etc... The keyboard is the chassis, you (generally) want it as stiff and stable as possible, that IS why you bought a heavy aluminum keyboard, right? Treat the switches like the suspension, the part you tune. Itís the only way to make it consistent across the entire thing or adjust specific properties and get a consistent outcome. If you want to type on a cushion with super soft landing get something with more travel and designed for a softer landing, like a rubber dome or Topre because other than the ones mentioned, MX style keyboards (and specifically the switches) just don't lend themselves to this.