This KBPC E keyboard will be made into a "true" split keyboard with a longer cable between the two keyboard isles.

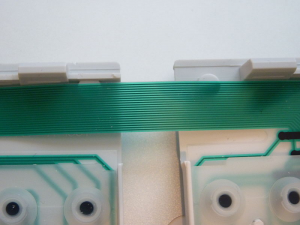

The most important thing is to figure out how to do the split. In the attached photo you can see the bridge cable between the two isles.

It's around 1 cm in width, and made of a soft plastic material. I have decided to use DB-25 connectors, since there are 21 connections on the bridge cable. So, the procedure is to cut the bridge cable and connect a DB-25 connector on each side. I haven't stripped and soldered anything like this bridge cable before, but since it's so small I doubt it's easy. One idea is to use some kind of block connector to screw on to the cable after having scraped off some of the plastic coating, and then run some wires from that to the DB-25 connector. I doubt there is an existing block connector to match the bridge cable. Machining or 3D printing a block that takes really tiny screws could work. Soldering wires onto the bridge cable directly would be preferable, if I can just figure out a way to do it. Any tips?