I'll watch for your progress.

Yes, the 3 pins are for num lock and caps lock (and +5).

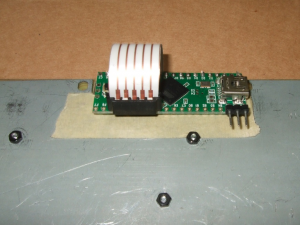

The controller is connected to the PCB by a 17 pin "right angle" FFC. This makes it very easy to assemble and disassemble but hard to take a picture of. Here is a picture of the top membrane fitting into a similar 5 pin "strait" FFC that connects the top membrane.

I wanted to share my method for assembling the key switch layers that solves one of the common problems when assembling a buckling spring keyboard.

The springs on BS switches are a little longer than the frame barrels are deep so that if the barrel frame top is flat against a surface then the springs will not seat properly. My previous solution for this was to use whatever junk i had on hand to wedge around the edge of the frame to prop it up. The problem with this is that a slight bump might knock one of the props loose and some of the springs will unseat.

I start with a box about the size of the keyboard and cut a hole just big enough to fit around the barrels. Pictures show it best. Also showing the assembly steps.

springs in and nicely seated

pad

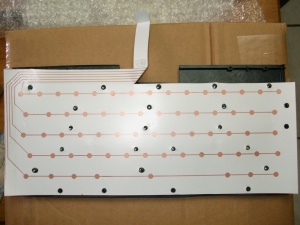

top membrane with contacts face up

middle membrane is clear, so it looks the same as the picture above.

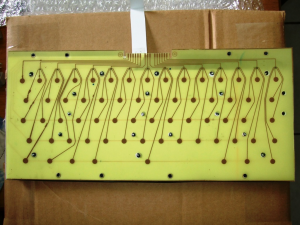

bottom membrane (OK, it is a PCB) with contacts face down

back plate

nuts on and controller attached. tape keeps LED wires from getting pinched.