Hi, sorry if it's not okay to bring up souch an old thread, but I just wanted to chip in to say this thread was a great help in making a custom acrylic plate for my new Alps build after finding it through Google, and I thought I would share my modified Tai Hao design from emdude's original, since I couldn't see that anyone actually uploaded one with the right shift fixed. I've finished the build and it works great.

TAIHAO v4 wider space stabs.dxf

TAIHAO v4 wider space stabs.dxf (85.45 kB - downloaded 81 times.)

I also modified the spacebar stab holes to be compatible with screw-in MX stabs as well as the clip-in ones, since this is much preferable to me and I would have thought most people, being that Tai Hao spacebars have MX mounts. I've widened them very slightly in this design from the one I got cut, as they were a pretty tight fit on acrylic and may be too tight with metal (the service I used had a 0.2mm mm cutting kerf, if that helps anyone). I didn't actually test the big clip-in ones but they should still fit.

I got this cut on 1.5mm engraving laminate by the way, which is a softened acrylic, as that was the only acrylic material I could find on a UK online service in the thickness range I was looking for, which was 1.2mm - 1.6.mm. I know this thread has mentioned 1.0-1.2mm as ideal, but I felt 1mm might be a bit loose for the switches to clip in and a bit flimsy in acrylic. When I measured the gap between the wing clips on the switches, 1.6m seemed about the max, and 1.5mm did work really nicely in terms of the switches clipping in snugly. I also didn't have any of the brittleness issues that I've read others have had with thin acrylic plates. The service was laserlab.co.uk.

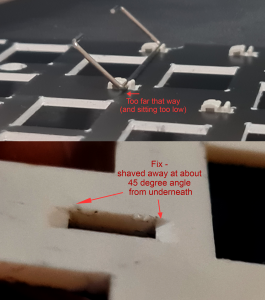

The only problem I had was that the small clip-in stabiliser holders didn't fit in properly at first because the plate was too thick and they wouldn't slot in the right place, resulting in the stabs not working properly at first. I just had to shave a little bit out of the acrylic with a Stanley knife and it was fine, as you can hopefully see in the pictures.

As another side note I originally ordered

this steel plate from KPRepublic, but I didn't look closely enough before ordering, hence doing a custom plate in the end. I'm a bit mystified as to what kind of stab solution this is designed for with the Enter key with the L-shaped hole - the slots seem to be for the bigger clip-in types you can get from Matias, but how are you supposed to keep the right-hand one in place? All I can think of is taping/gluing it to the PCB somehow but that doesn't seem ideal. Or are there other common Alps keycaps with MX mount stabs so you can use screw-in ones? I'm working with ANSI here but it looks like you'd have the same problems with an ISO enter too.

Attached an image of the finished project too since I think it looks quite nice... YMDK walnut case, Salmon Alps, Tai Hao Tomcat caps and XD60 PCB.