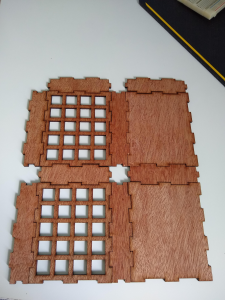

You wasted a bit - the top and bottom ends could have been side by side

Seriously though it's a good design and should be quieter than a sandwich case, if that's something you want.

Thanks

I am assuming that you mean to arrange them like this. That is enough for two of the cases. That does use less material though which is cool

I think I can reduce the height of the case from around 25mm to 15mm. I think that's enough space for switches, pcb and a pro micro below. It also makes adding a usb cutout more accurate than if it was a 5 layer (3mm each) sandwich case.

I really like quiet keyboards, but I'm curious as to why you think this method would be quieter than a sandwich case.

If it was compared to a sandwich case with 1 bottom layer, 1 plate layer, and 3 open layers (just the outer rim). The internal volume would be the same, and therefore the same amount of sound damping material can be put inside. I'm not sure about what other factors affect the sound that would be relevant here.

The main issue I have with this case design is if it's arranged and cut as shown above because of the kerf, the pieces need something to hold them together as there isn't enough friction between the joints. It is just about stable enough to put it together and take a photo of it. I could glue it together, but that makes it impossible to fix any issues or modify anything as it's stuck together.

Maybe I could glue the top to the 4 sides and use magnets to hold the bottom in place, but I'm not sure where I would put the magnets.

Instead, I could make the sides much thicker (around 6mm maybe), and put self tapping screws into the top (and bottom) plates and then into the sides. Although, the wood would probably splinter and break apart as the screw goes into the side of it. The layers of the plywood would probably split apart as the screw goes into it, also there is probably a limit to how many times a screw can be put in before the hole is too big for the screw to hold properly. The sandwich case is probably a better design but it uses about double the material and it needs standoffs.

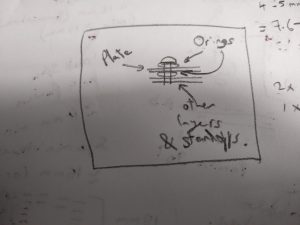

I did have a wacky idea the other day to put o rings on the screw around the plate to sort of make a gasket mount. It would leave an air gap between it and the other layers however. I don't know how well it will work to alter the sound and feel unless I try it. If the screws are around the outside of the keyboard then the switches and PCB would only be in contact with the o rings and maybe some damping material below the PCB. It might also need a larger hole so the screw isn't in contact with the plate layer and also some washers to hold it in place as the inner diameter of the o rings might be larger than the diameter of the screw head.