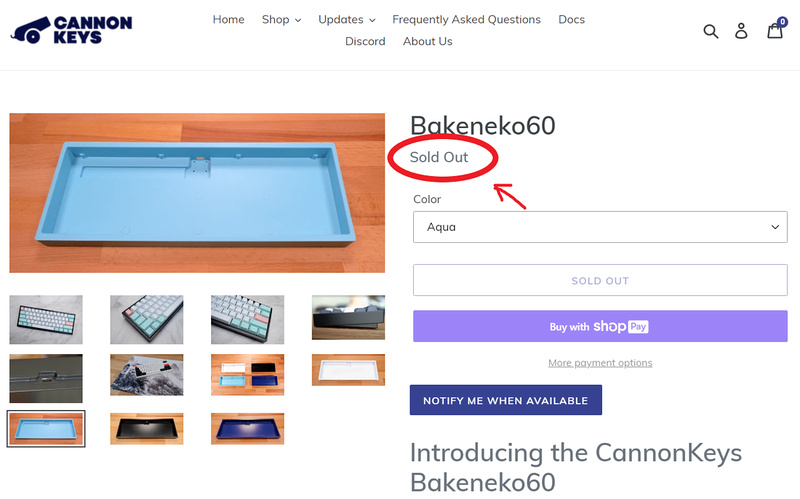

I just got into mechanical keyboards a few weeks ago, and was looking for some affordable options that had the latest fun-filled features. One of the keyboards I saw a whole bunch of spicy Youtube videos about was the Bakeneko. . . an "in stock" budget keyboard perfect for someone like me. Jokes aside, it's pretty frustrating trying to start into this scene with everything good being out of stock perpetually. So, I was looking for some fun off-the-shelf options that I could play with and that I could repeat readily when the inevitable friend comes knocking.

For the Bakeneko, even with a couple of high volume drops, it's only sad face for me

So I went looking for some alternatives like this

KBDfans Anode Aluminum Case %60 --> Bakeneko

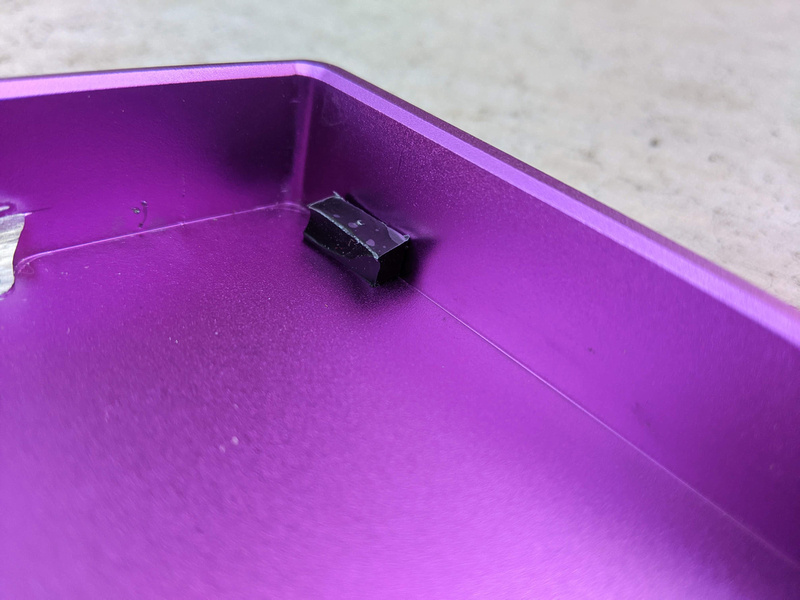

The main trick was hacking these little cutouts in the case for the O-ring gasket to clear the Durock V2 screw-in stabilizers.

And hacking off all of the PCB supporting bits from the case.

With all of the supports hacked off, I'm using 3/16" thick medium hardness Sorbothane as supports, and these can be placed wherever you want on the this particular

KBDFans Anode Aluminum %60 Case Bakeneko. Sure, it's pretty expensive material if you plan to do something silly like line an entire case with it, but I'm using literally scrap quantities. The 4"x4" square that I bought will last me forever at this rate of use.

For this case I'm using a 9 inch diameter 1/8 inch thick Silicone O-ring that is 50 durometer. Mine was purchased from McMaster Carr as an in-stock (for real. . . it's in stock) item. Depending on the case being used and the gap between the PCB and the case wall, you can use different diameter Silicone o-rings to adjust. The more you stretch the o-ring (smaller diameter), the thinner the overall gasket is. For his case, the gap is quite large between the case and the PCB, so 9 inch sized o-ring used here is the maximum diameter possible and there is no stretching at all when wrapping this size o-ring around a standard 60% PCB.

Because the side wall of this case are pretty thin, be careful when making the cutouts for the backspace key stabilizers as you can cut straight through the case like I almost did. . . don't be me!

Next, I also tried the

KBDfans 60% Wood Case For DZ60 GH60 Wood Bakeneko

This one was pretty cool because I don't see a lot of wood cases out there with modern gasket-type mounting options. Thanks, KBDfans for your innovation! I'm re-using the 9 inch diameter gummy worm gasket here, but the case gap is smaller here than on the anodized aluminum Bakeneko above. I will need to experiment with a smaller diameter one. 6.5 inch is too small.

I do not know what the proper size is, but I think I may try out 8 inch and see how that goes. The 9 inch works and fits, it's just that I do not get as much of the satisfying PCB movement and I would like to optimize that a bit. (EDIT: The 8 inch diameter 1/8" silicone o-ring works better than the 9 inch one in this wood case!) I find the sound on the wood one to be quite satisfying though with a lot of interesting variation especially with this aluminum half plate setup. . which was provided by Dremel.

The rest of the internals are very similar. . . I yanked out the brass standoffs with pliers and then used a dremel to cut out all of the perimeter PCB supports. A flush-cut router would have made quick work of everything, but when all you have is a Dremel, you kindof have to go with it.

For this case, I am using 1/8" thick Sorbothane for PCB supports. This thickness is almost perfect in the application, and Sorbothane without any additional adhesives sticks LIKE CRAZY to the bare wood and wood finish on this case. It is really not going anywhere. . .actually, if you try to remove the strips after installation, bits of it will be stuck to the wood.

The rest of the cutouts are about the same as before except the case wall is thick enough that there is no danger of cutting clear through.

Here are the spacebar stabilizer cutouts. Assembly and disassembly starts by inserting the butt end of the PCB along with the USB socket in the case first and then pressing the front edge of the PCB in. . . so relief cuts for the spacebar cutouts allow the board to install and remove easier while still locking the entire assembly into place better than the original Bakeneko design.

Next, I also tried the cheapest option which is the

KBDfans 60% Plastic Case Plastic Bakeneko.

This one had the funnest flex of all the options but required the most cutting of the support spines inside the case.

The gaps are small, so a 6.5 inch diameter gummy worm o-ring is used here like suggested for the Tofu versions EDIT: the 8" diameter O-ring works better in the plastic case providing better contact around the perimeter.

For rear PCB supports, I am using some EPDM rubber tubing left over from PC water cooling projects. This stuff is 1/16" wall thickness which worked out perfectly on the existing support spine.

And, after cutting out the necessary plastic support spines to allow flex clearance, I'm using 1/8" thickness Sorbothane strips for the front PCB supports.

These are all of the Bakeneko's I've been able to find in stock at the moment. I'm sure there are other ones out there like the really cool

Baldr glass Bakeneko case that is in group buy right now.