Closed while I'm at school and have to fit my whole life in an 8x8 roomHi there everyone, I've recently gotten into keyboard modding, and have done some boards of my own, and have some more in the queue from family members. I find myself enjoying this sort of work, and am willing to offer my services to the GH community at competitive prices. I'm located in Southern Ontario, near Toronto, and am accepting work from any Canadian, or anyone else who's willing to pay for international shipping.

Services offered:

- Switch swap (raw switches or from a donor board)

- Spring swap

- LED mods

- Controller swap

- Lube jobs

- Switch Stickering

- Cleaning and General Maintenance

- Keyboard Repair

Note that pretty much any of this will void the warranty of the keyboard in question. I do not have any formal training in soldering or electronics work, although I haven't broken anything yet. I do this work at below minimum wage, and because I enjoy helping out the community. In the event that there are problems with a board in my possession, I will contact you and we can work out some form of compensation. I will only be accepting one board at a time, and would ask you not to ship your board until I have shipped the previous board to its owner.

I am planning in the near future to offer custom paint jobs for cases as well, assuming I can get a proper painting setup that can give me the best results possible.

If you're looking for a keyboard related service that's not on the list, feel free to contact me so we can discuss it.

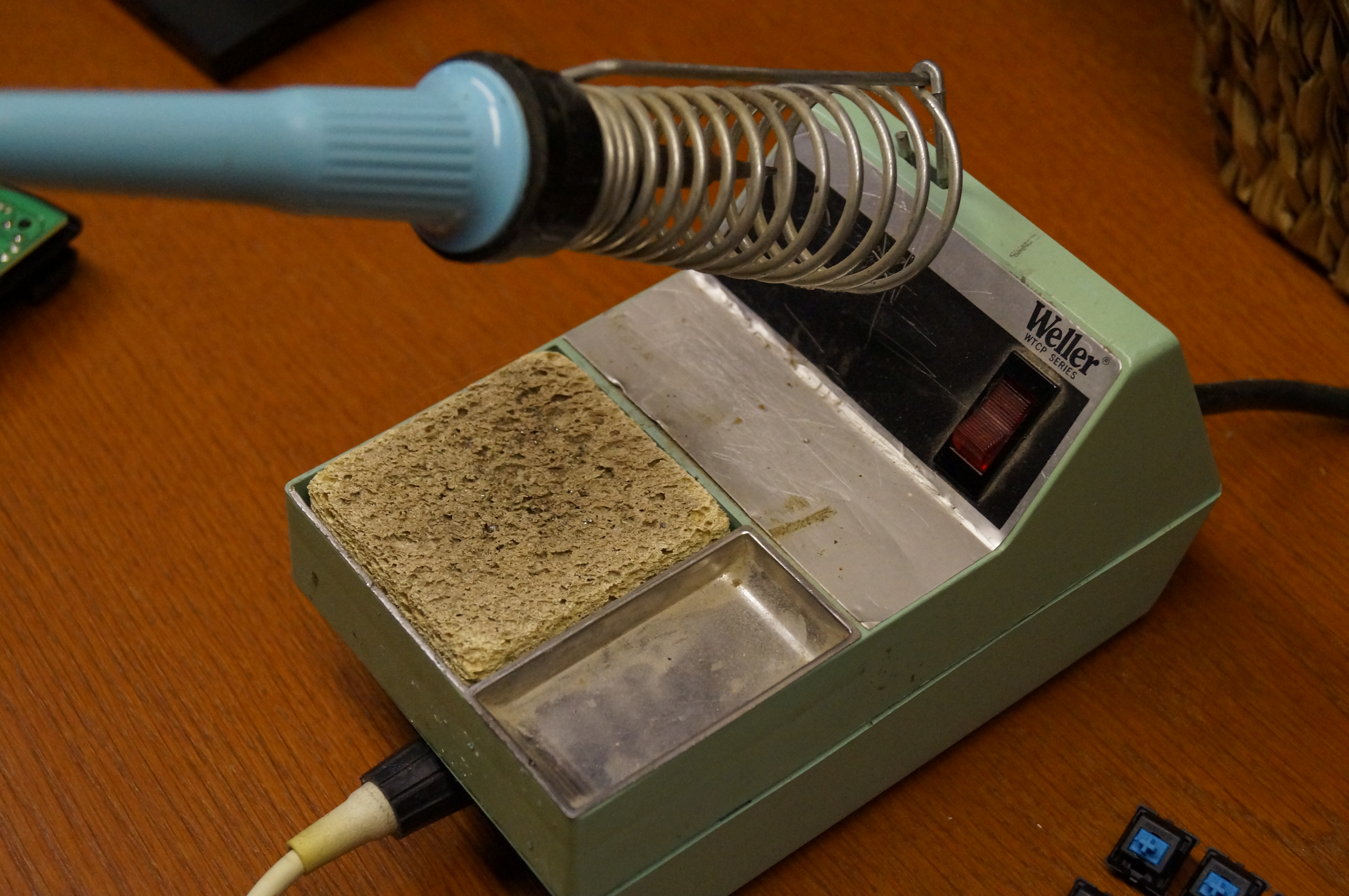

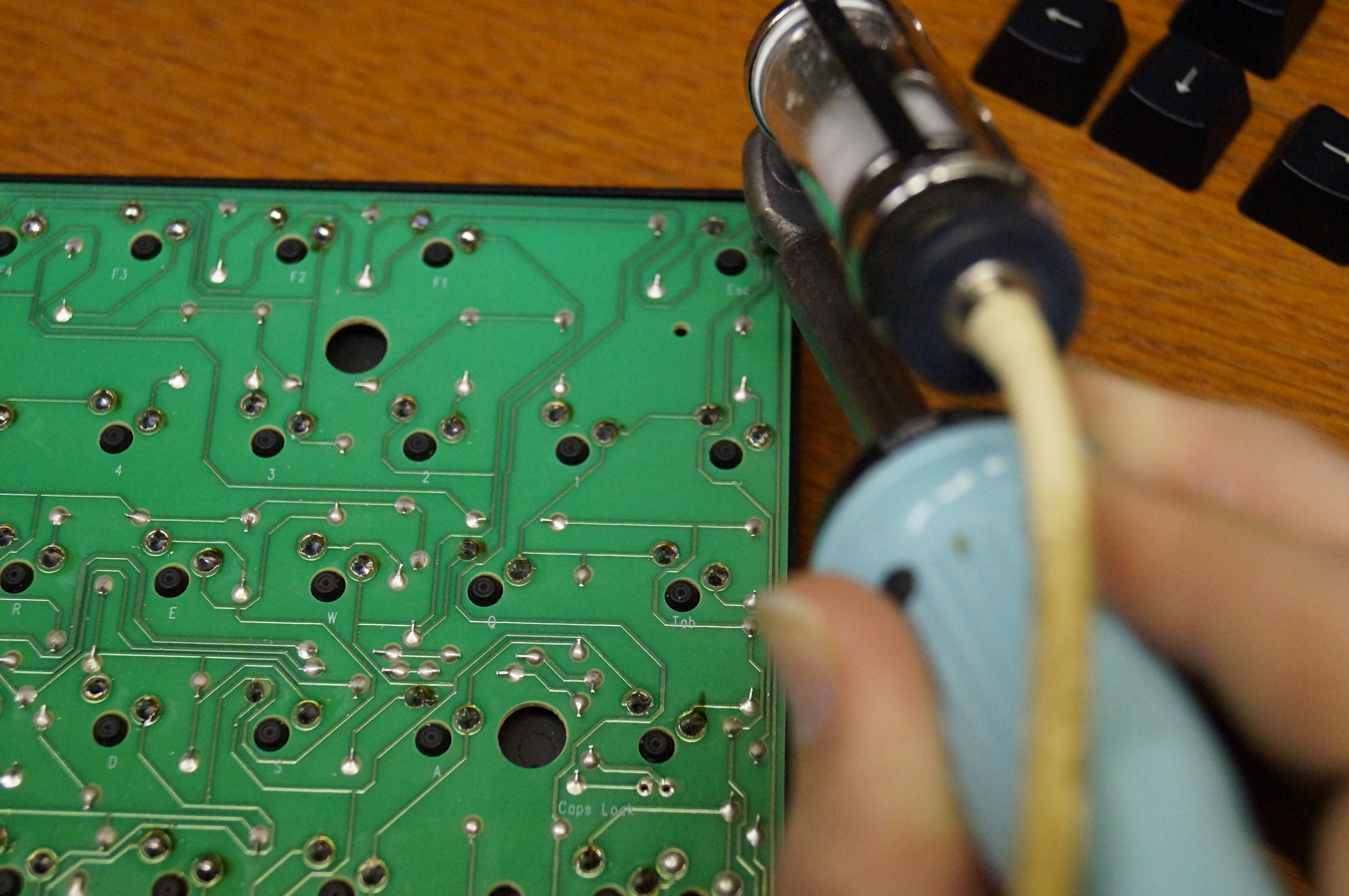

For all soldering tasks, I use industrial-grade Weller equipment. I have a DS600 desoldering station with an integrated vacuum pump solder sucker, and a WTCP-TC202 temperature-controlled soldering iron.

For application of lubricant, I have access to medical-grade sterile syringes and needles, to ensure that the debris entering the switch is kept at a minimum.

If you're interested in any of the above, feel free to drop me a PM. I usually respond within 24 hours, and often sooner.

I'll be adding some pics of my equipment and my current personal project in the near future, once I have access to the nice camera again.Got some pictures, sorry it took so long. All the equipment shots are courtesy of my sister, who is a much better photographer than I.

Desoldering station, Soldering iron, Multimeter

Desoldering station

Desoldering tip detail. I have a couple different sizes of these, this was the one I used for my QFR switch swap.

Soldering station

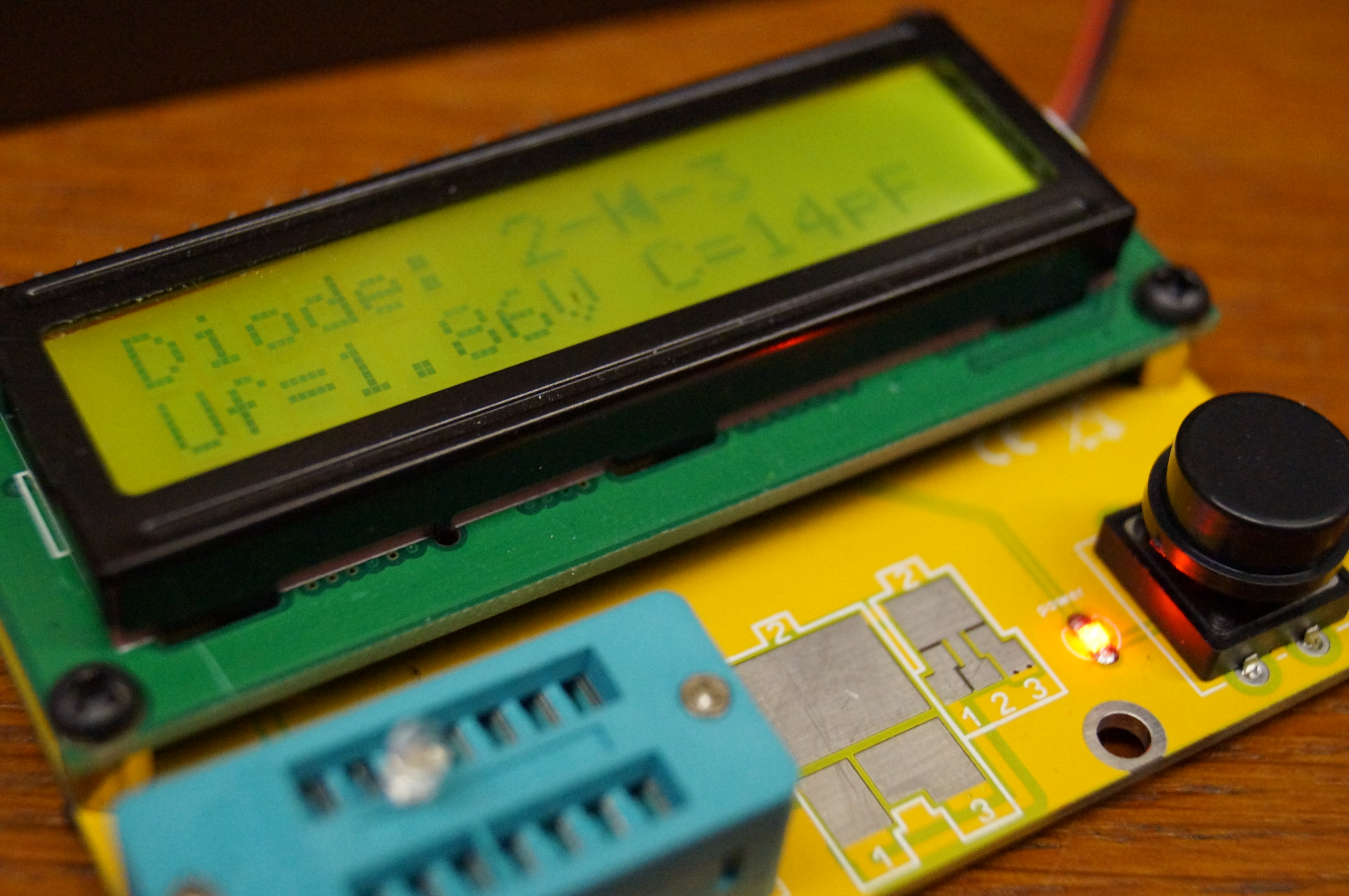

Diode tester. It works on resistors, capacitors and other small components as well, but I mostly use it to make sure I hook up LEDs in the right direction. It can be useful for knowing what resistors to use to match LED brightness too.

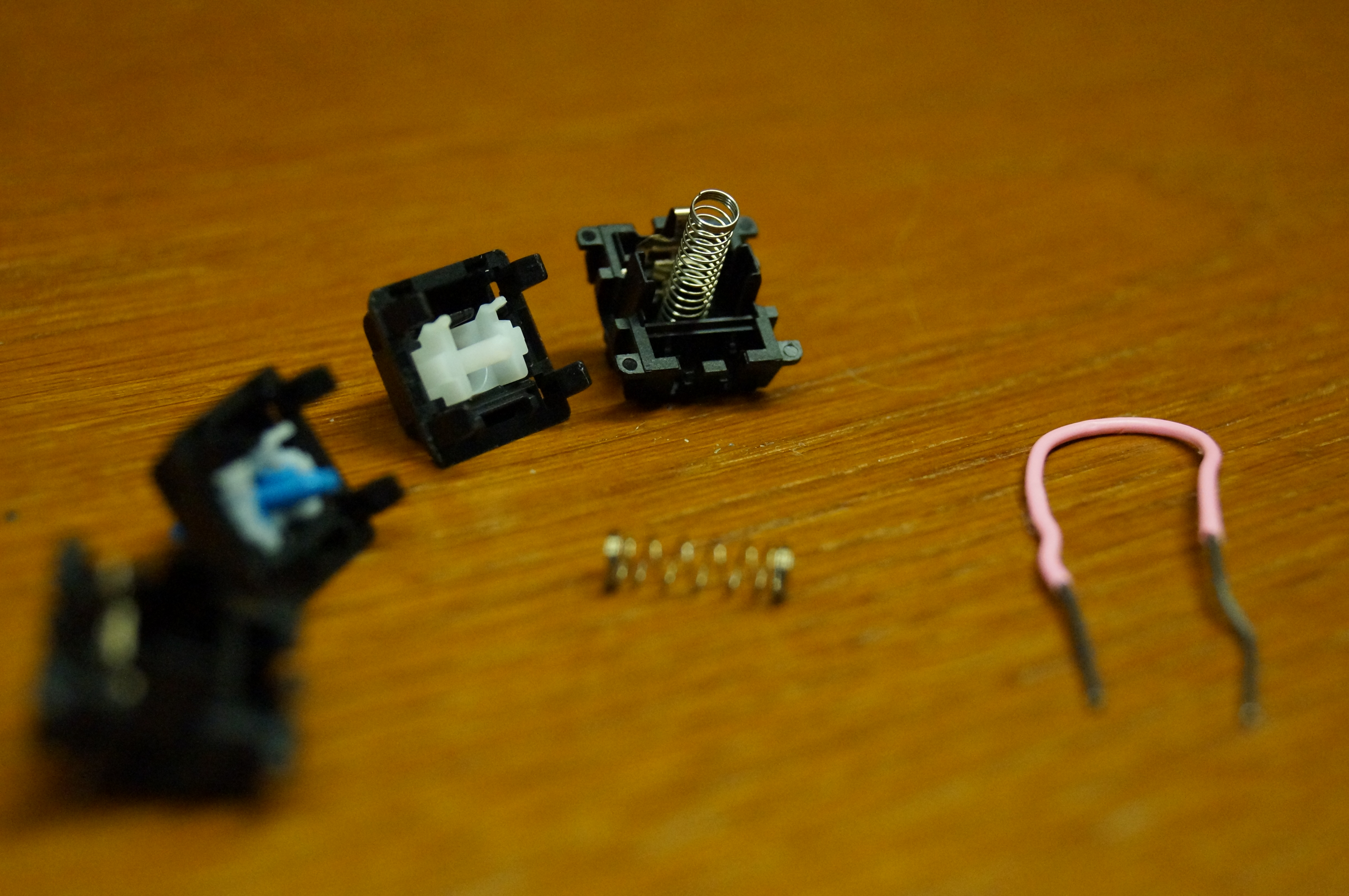

Spring swap in progress. I ended up swapping these springs back, as I was happy with the heavier clears.

And some WIP shots from my QFR:

First switch coming out!

About halfway done with the desoldering process.

Everything out. I soldered in the four corners before I was done taking all the blues off so my PCB didn't separate from my plate.

Clears, waiting to be converted to plate mount.

I forgot to take a picture before I had all the keycaps back on, so I pulled some off again for this shot.

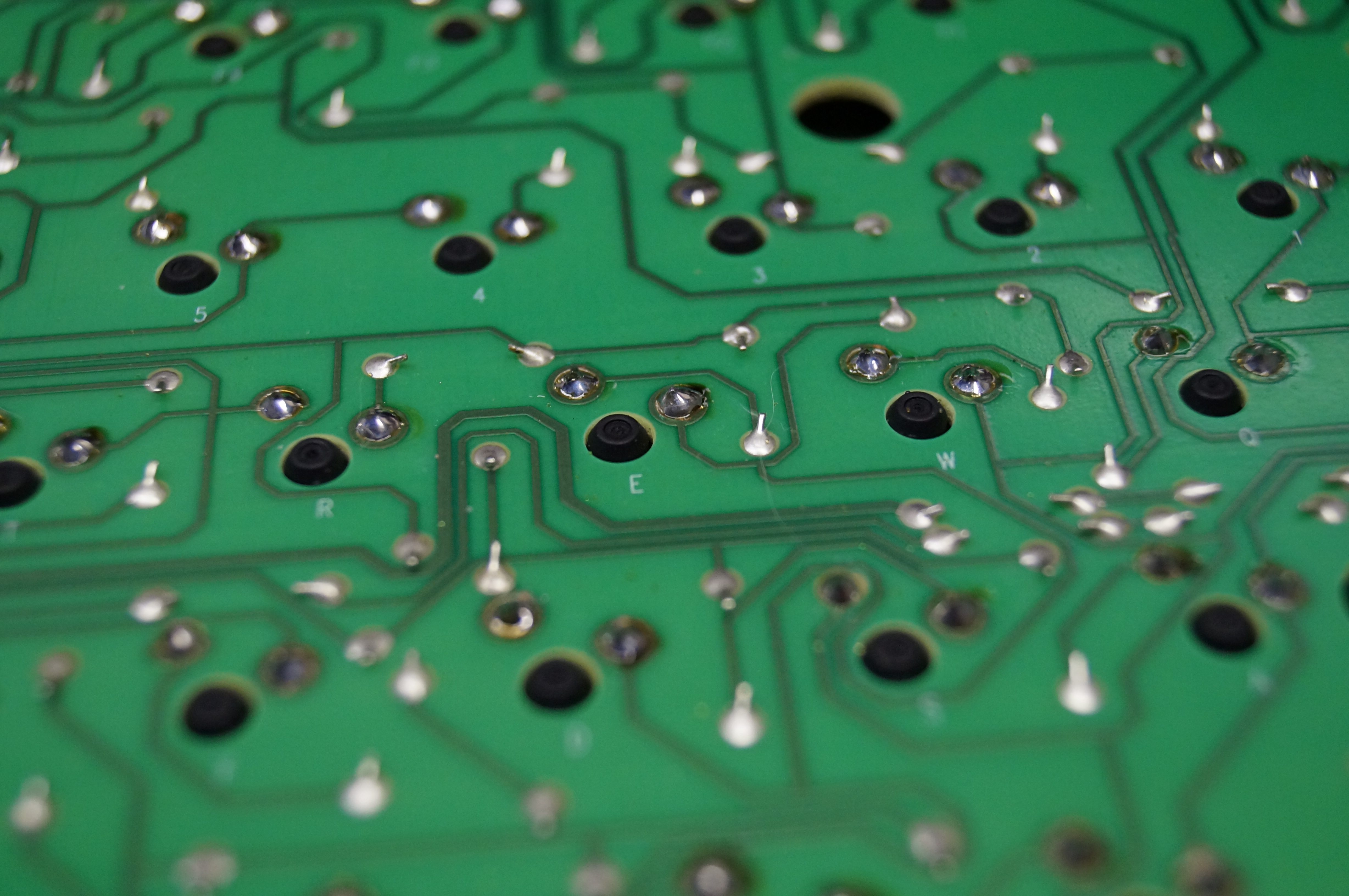

Detail from the back on some of the solder joints. I didn't bother cleaning the flux off because the board was going back in the case immediately. Q looks a bit like a bad joint in this picture, but it's just the lighting.

I haven't soldered the LEDs back in because I'm planning to move them to a different location on the case, as the keyset I'm going to put on here isn't windowed. I'm looking at the feasibility of putting them in the same place they are on a filco. Got to figure out if there's a good way to route the wires though. If there isn't, I'll probably end up putting the LEDs back where they were originally.