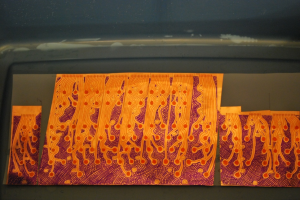

I tried my hand at doing a custom M membrane a couple of years back:

The M has the advantage that parts are readily available, both on the used market, and also from Unicomp to some degree.

I ended up getting waylaid by the F, so ultimately I hope to approach the M->nkro/custom layouts problem very differently next year via an F-conversion of some sort... here's hoping. :)

So - my biggest fear is that the the silver printed pads and copper base will electrocorrode, or the base will work harden, or stretch and bump up, etc.. under the small, but unending impacts of the M hammers.

Two things I found that helped a bit, is like on the F, you want some sort of level base for the hammer feet to rest on to the upper right and left of each contact. My samples here don't have that, but you can see the spots I mean as they leave two dents on either side beside each hammer dent on the rubber mat above.

Another thing is that you want a fill - a subsequent attempt I was intending to combine the fill with the pads above. The fill serves to reduce the load on the acid when etching and make it easier to get a sharp clean cut with less undercutting, pinholes etc...

Doing multiple small etches also helps when at home.

My intent was obviously to do a diode array on the controller, rather than try to mix it in with the matrix, adds cost in connectors, but avoids many questions of wear over time.

If I were to do it again, my intent had been to slice up a couple of normal M membranes and pull out the matrix entirely, avoiding any rework of the M switch which is an old, well tested, long-living mechanism.

These days - I have explored more about ordering thin pcb, and it is much cheaper than custom membrane for small orders. I'd have them finished in thick nickel to more closely match the electro-corrosive constants for the silver ink. Stuff you might want to explore when you next want to do a full redesign - clearly this path you are exploring is bearing too much fruit to not follow to its end. :)

Also - silver plated copper particle inks are an alternative to pure silver inks, and somewhat more economical.

Great progress, though - and so pretty!

dfj