So I have been getting quite a few PM's regarding this topic, and wanted to share what I personally know and do for lubricating Cherry MX switches.

First off, why lube Cherry MX Switches? For starters, adding lube to sliders gives a smoother feel to the switches. Especially in MX Browns, which seem to be inherently 'scratchy'. Or in the case of MX Blues, would make the tactility smoother, and lower the clicking sound, depending on which points you lube the stem at. The natural friction between the stem, spring and switch housing can be eliminated by using lube.

On the topic of what type of lubrication to use, there are several choices available to you:

1.

Krytox GPL-105 Higher viscosity, better for using on sliders

2.

Krytox GPL-103 Lower viscosity, should be fine for all lube points

3.

Krytox GPL-100 Lower viscosity, should be fine for all lube points

3.

RO-59 4.

Teflon Silicone Lubricant A low viscosity lubricant, good for all applications

5.

Krytox GPL-205 Grease A heavier substance, recommended for everything but clicky stems.

And many, many more options at your disposal. Our friend limmy has

posted an in-depth guide on the characteristics of different types of lubes and greases (thank you limmy, really great information there). The choice is yours as to what type of feel you are going for. You may also want to participate in the

lube group buy going on at Deskthority as well.

For this guide, I am simply covering the friction points and where you would typically want to place lubricant.

For starters, let's go over the primary locations for lubricating:The illustrated points show where the spring makes contact with the bottom of the switch housing, and the stem contacts and slides against the housing.

Original image (broken link):

More

Since I started doing this, I have only been using the teflon silicone lubricant. It seems to work pretty well all around for any one of the lube points. (I can see where grease may work well on the sliders, and will probably be tinkering with that in the coming weeks. I will post my findings and update this thread at that point).

You really want to be careful not to over lube those areas, but rather dab it on very lightly with a brush or Q-tip. Over-lubricating may interfere with the switches contacts if it happened to spill off into that area, so you definitely do not want to overdo it.

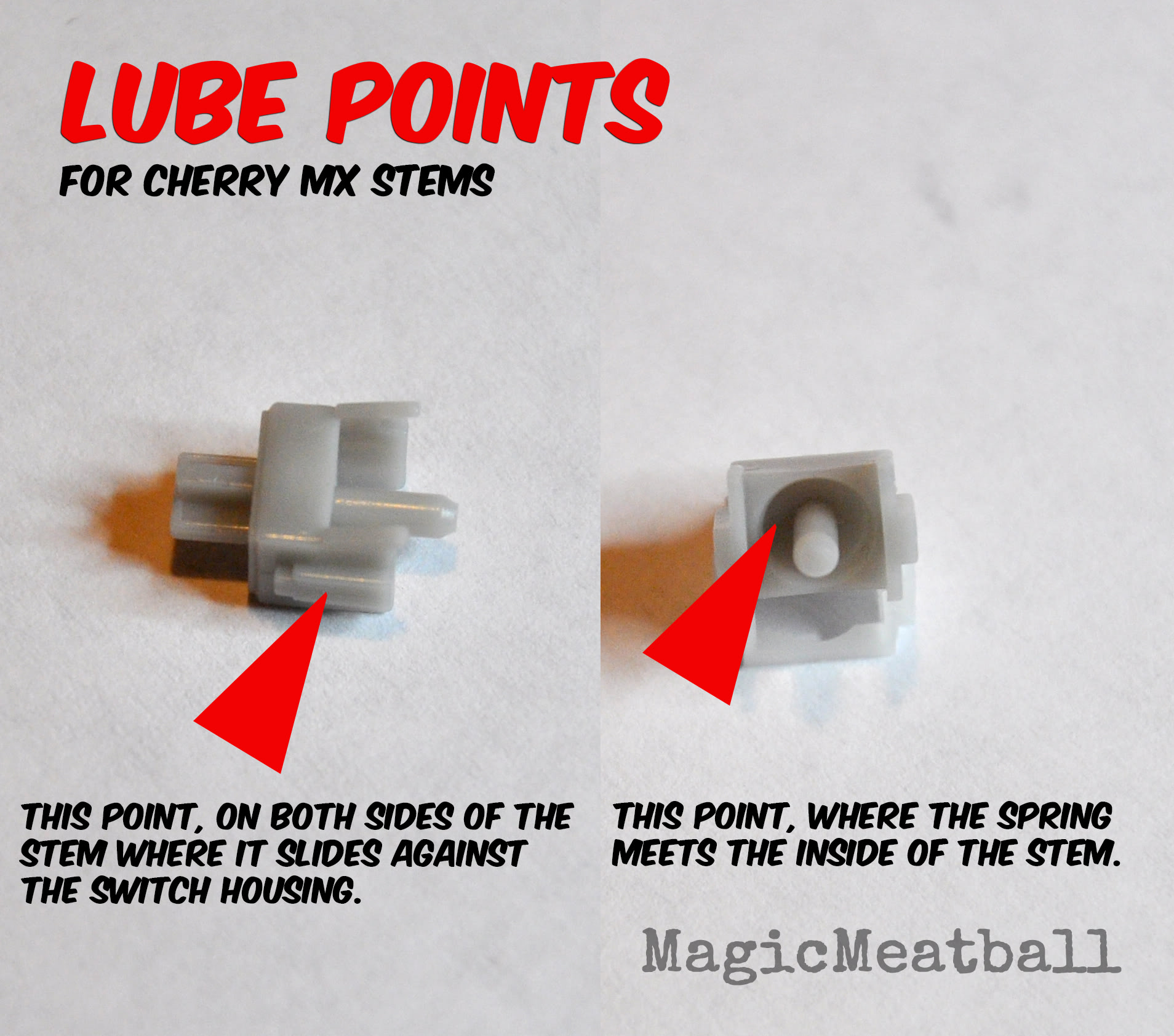

Next up, lubing the stem:The following photo illustrates the points where the stem contacts with the switch housing and the spring. The sides of the stem will come in direct contact, and slide up and down along the inner sides of the switch housing. The spring will fit into the inner part of the stem.

Original image (broken link):

More

Lubing a 'clicky' stem:This is still experimental for me. I am not sure how many, or if anyone else does this. Basically, I lube the slider section of the upper part of the stem (colored part) as illustrated in the photo. This has proven to be tricky, as adding too much will cause it to stick, and you lose most of the 'click' sound, as well as some of the tactility from the slider separating and engaging with the stem. Applied in very, very small amounts, the teflon silicone lubricant worked quite well, and quieted the click very slightly, but enough to still be there. When I tried using the Krytox GPL-105, its viscosity was too dense, and caused the slider to stick.

Original image (broken link):

More

*Note: Stem assembly taken apart for reference only. You do not need to actually separate the 2 stem pieces to lubricate. A fine brush should work great for getting in between the two pieces to lube.My method for applying lube to specific parts, let's start with the spring:For the spring, I use a q-tip to apply a fair amount of lube (teflon silicone) to each end of the spring. I lube one end, then place that inside the switch housing, then the other end while it's sitting in the housing.

Original image (broken link):

More

What I use for applying very small amounts of lube to sliders:I do have a brush, but even sometimes a brush gives you an unanticipated amount of lube. The quill pen can be dabbed with oil and will release a very tiny amount when pressure is applied to an area.

Once you have applied lubrication to the specified areas, put the housing back together and test it out. You will probably want to experiment with different lubes and amounts to get the switch feel that suits you best. Everyone has a preference, and I can't guess that for you, only give my recommendations.

I will be updating this guide as more information becomes available. I have just ordered some Krytox GPL-205 Grease, and plan on experimenting with different mixtures of oil and grease.

Again, this is simply my method for doing this, if I am wrong on anything, please feel free to offer constructive feedback.

Updates:

Updates:Adding

DanGWanG's superbly uplifted video on lubing:

Just received my metal lube station in the mail. It's going to make my life a lot easier, sho nuff.

« Last Edit: September 16, 2012, 05:38:27 PM by MagicMeatball »

« Last Edit: September 16, 2012, 05:38:27 PM by MagicMeatball » ^^ For posterity

Mod Edit: Reuploaded some of the broken image links with images that I had / could find. PM me if you have more.